|

||||

Review of a Kent Rasmussen pipe Well, where to start…. This review is going to be a bit extended and I have to let you in on one of my “problems” first. I have been collecting high grade pipes from Danish pipe makers for some years now and I have a small (but nice) collection. Small, due to the fact that the pipes I’m talking about here is quite expensive and also hard to get. On average, a maker of high-grade pipes is making from 80-250 pipes a year. Many of them is ordered in advance by collectors and distributors so you can imagine how few there will be left to cover a worldwide market. Regarding the price for these wonders – well they are worth every penny. If you look at it as a pure investment, it is not a bad one. You can enjoy your wonderful pipes for years and if you decide to sell them, you are most likely to get your investment back and often with interests – even if you have been smoking them… If you at the same time get the joy of owning a small masterpiece that is so unique, that no one has something exactly like it, you got your second “bonus”. For me the biggest joy is to hold and observe the result of the effort and skills the pipe maker has put into my pipe – the trouble he has been through selecting the block, turning it around to find the perfect cut, where the grains in the wood and the artist works together to create the best possible pipe; the precise drilling of chamber and air hole; the handmade stem, that completes the shape of the pipe and the final staining and finish… Well, this joy also turns into my problem – the more I learn about the pipe makers and the process of making high grade pipes the harder it gets for me to light a fire in the middle of these pieces of art. Ridiculous and stupid, you might say – and right you are, pipes are made for smoking, and no smoke without a fire… (To justify I’m not a complete nut, I will add that I have many pipes that has been smoked - and taken care of – well over the years, and they all has the beauty and personality that pipes get when they accompanies you through good and bad times – and I love them…) Enough talk. I recently got hold of a beautiful Kent Rasmussen pipe – sandblasted, since I find it easier to overcome my “problem” with a sandblasted pipe, and I really wanted to smoke one of his fantastic pipes (I already have two of his smooth pipes in my collection, un-smoked of course). Smoking this pipe is a positive experience beyond many of my previously experiences – this pipe is special in so many ways and smokes more than perfect, so I decided to find out more about it and the way Kent makes pipes. A few clever guys that I met at the Chicago Pipe Show showed me how to examine a pipe and what to look for in order to judge the smokability of the pipe – without actually smoking it. This knowledge came handy now. |

||||

|

|

|

||

| Click the pictures... Using my “Streamlight Stylus” examining the pipe, I soon realized that the stem work was quite exceptional – and I am talking about the inside and “hidden” areas of the stem – the air hole, the slot and the tenon. Everything is so precise and well made and it seemed that the air hole it self has been polished… It has the exact same “bumper to bumper showroom shine” as the outside of the stem – something I only have seen on two other pipes (also made by Kent). Have you ever tried to close a door in a Rolles Royce? If not, you get the same feeling when you mount the stem to the shank on this pipe. The tenon fits the mortise with a precision that makes you cry. Of course the diameter of the tenon fits the mortise “hole”, but also the length of the tenon has an exact match of the mortise, leaving on extra room for turbulence and dirt. The shank face and the stem face has an exact match too, leaving absolutely no room for even the tiniest hair - and the almost invisible countersink between the shank face and the mortise leads the tenon smooth and safely into its tight dock. The tenon is of course also equipped with a countersink inside around the air hole and a tiny one outside to make a smooth connection with the mortise. |

||||

|

|

|

||

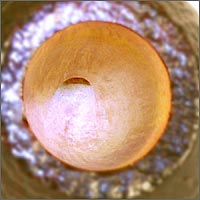

| Click the pictures... Looking at the inside of the shank (mortise and air hole) you find the same extreme precision and perfect finish that you will find everywhere else on this pipe. The inside of the air hole has carefully been sanded to a nice clean and smooth surface that allowes a clean draft with nothing to catsch tobacco pieces. The connection between the air hole and the tobacco chamber is also rather special. It goes without saying that the air hole is 100% centered – and you would think that it also ends up exactly in the bottom of the chamber – well, wrong… Kent drills his air hole to end up one millimeter or so BELOW the bottom of the chamber, and then carves a small “sump” into the wall and bottom of the chamber. This gives a perfect smoke with an easy airflow from the chamber into the air hole. Furthermore it allows you to smoke the pipe nice and dry all the way to the bottom. |

||||

|

|

|

||

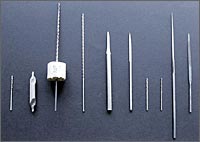

| Click the pictures... The inside of the tobacco chamber is virgin wood, of course sanded to a perfect smooth surface (another thing that I just love – but boy it makes it hard to build a fire in a chamber with Straight Grain walls inside)… After examining the pipe carefully and smoking it a few times, I decided to call Kent to learn more about his work process, since I realized that I here had something very special. A meeting was arranged in Kent’s workshop. A couple of years ago I got a new titanium hip, and I remember the kind doctors explaining me the operation and showing me all their “wonderful” tools that has cleverly been designed for this special task – well, I almost had the same feeling in my belly when Kent proudly showed me all his tools for making stems. He has a large number of custom made drills and files (made by himself) including equipment to polish the inside of the air hole (he really does that). |

||||

|

|

|

||

| Click the pictures... Kent explained in details how a stem is born, and soon I was wondering how he manage to earn his living – his pipes should cost the double of what he is asking (I didn’t tell him that…) I was planning to make sketches alongside a detailed description of every step Kent goes trough making a stem, but it would take me a full week end plus I should get a bigger server, so I will try to explain only the most vital step in as plain English as I can manage: Kent is using German Vulcanite rods (rubber) for all his stems. After turning a raw piece of rod into a perfect round shape he starts drilling the air hole and making the “bed” for the tenon and often also a piece of exotic wood. The air hole is made in a number of steps, where he drills from each end of the rod using many different drills. Kent start the air hole by drilling a 1,6 mm hole from the Lip-end (depth 22 mm). Then he turns the bed for the tenon, drills the hole for the tenon (a separate piece of teflon-like material). The tenon is now mounted to the stem. Here after he can drill another bit of the air hole. Starting from the tenon-end he drills a hole with a 2.5 mm drill to meet the first drilled hole. This hole is drilled once again with a 3 mm drill. The first hole (in the Lip-end) with a diameter of 1.6 mm is opened up to a width of 16-17,5 mm to form the end of the Lip. The height is kept 1.6 mm to ensure that the final outside height of the bit can be kept 4 mm. |

||||

|

|

|

||

| Click the pictures... Exotic wood and a ring of vulcanite (to form the stem face) are added. Now Kent can start the huge task of shaping the stem and giving its perfect finish - inside out. Several hours later a perfect stem is born… The exact same care is of course put into the other half of the pipe (bowl and shank). This great care and attention for even the smallest detail gives a perfect smoke and a pipe that is easy to maintain and that will last more than a lifetime. When this great “smoking machine” then is being “disguised” as a true piece of art – almost a sculpture – in a perfect carved, grained and stained block of briar, you have the ultimate pipe (at a price that should been the double) – what more can you ask? Your investment is secure (even if you decides to build a fire in it…) I’m not going to say a lot about the appearance of my new Kent pipe – the whole idea of this review was to find the secret behind the great smoking pipes from Kent Rasmussen I will let the pictures speak for them selves. The only thing I will say is: Get one… Kent is not making that many pipes a year, and soon he will be spending all his time changing diapers on his first born…… Lars Kiel, July 2002 If you want to read more about Kent’s pipes, you will find a review on the great website of G.L. Pease, who also sells his pipes. You can also find a fine selection of Kent Rasmussen pipes at AAB-PIPES. You can also read more about Kent on this website Go for it… |

||||